All-in-one Warehouse Storage Solutions

Meet your personalized customization needs

Twenty years of experience in warehouse rack storage, customized design solutions for customers, efficient production, installation, and delivery, and 3-hour service response.

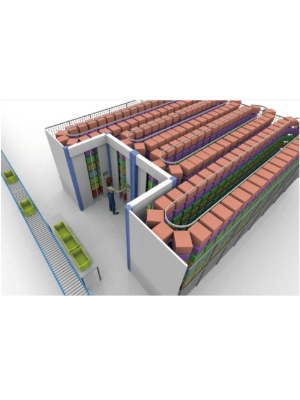

Automatic Rack System of 4-Way Shuttle

The Automatic Rack System of the 4-Way Shuttle is composed of a four-way shuttle, three-dimensional rack, automated conveying system, wms/wcs system, etc. Goods can be transported to any location on the shelf to achieve all-around three-dimensional warehousing, sorting, and sorting.

- High Intensity Storage

- Automation and Intelligence

- Flexibility and breadth

- Scalability

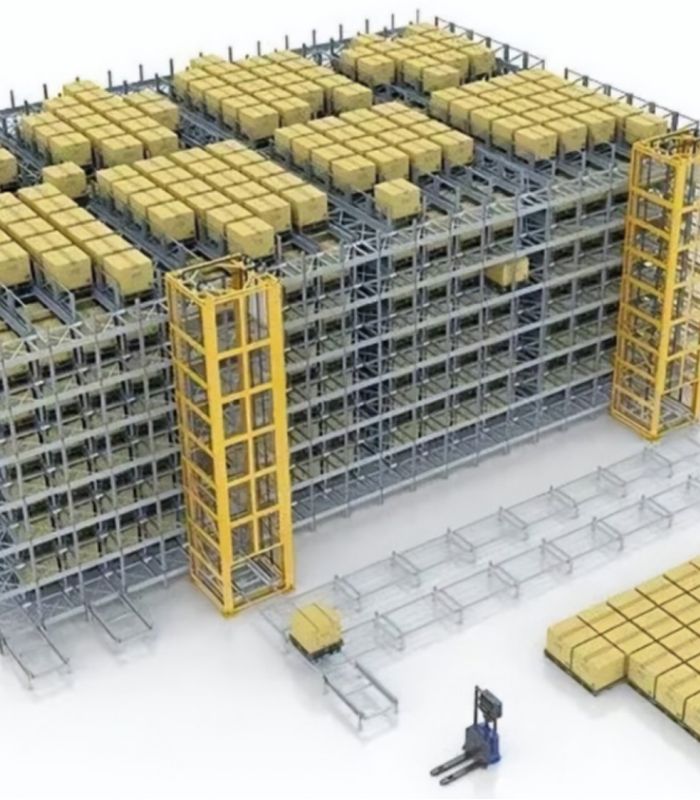

Pallet Stacker Automatic Warehouse

It consists of three-dimensional shelves, stacker cranes, conveyors, handling equipment, pallets, management information systems and other peripheral equipment, and is capable of automatically completing the storage operation of goods and the automatic management of stock positions according to instructions.

- Improved warehouse space utilization

- Saving labor and time

- High degree of automation

- Highly adaptable to the site

Selective Pallet Racking

Selective pallet racks are the most widely used in the warehousing industry. They are composed of column pieces (columns) and cross beams. They have a simple structure and strong applicability.

- High load-bearing capacity

- High space utilization

- Structural stability

- Easy to manage

Mezzanine / Steel Platform

The mezzanine/steel platform makes the best use of space. Increasing the storage area in the form of a mezzanine is suitable for situations where the warehouse is high, the goods are small, manual access is required, and the storage volume is large.

- Making the most of vertical space

- Suitable for a wide range of cargo storage

- Increased efficiency

- Adaptation to special industry needs

Drive-in Racking

Compared with storage racks, the space utilization of drive-in racks can be increased by more than 30%. The access method is first in last out or first out (entering from one side and exiting from the other side is first in first out). They were widely used in cold storage and food and tobacco industries.

- Efficient use of space

- Multiple ways to store goods

- Improve storage efficiency

- Reduction of transportation time

Push-in Racking

Push-in racks, also known as push-back racks, are made by overlapping multi-layer trolleys between the front and rear beams. The stacked goods are placed on the trolleys and pushed in from the outside. The goods stored later will push the original goods inside. When picking up the goods, the rear goods will automatically slide out along the track. It is a first-in, last-out access mode, which is suitable for the access of a single type of goods.

- Highly pickable

- First-in, first-out principle (FIFO)

- High space utilization

- Suitable for storing large quantities and small varieties of goods

Mobile Logistics Equipment

Stacking racks, folding storage cages, steel pallets, forklifts, lifting platforms, etc.

Detachable Stacking Rack

Foldable Storage Cage

Counterweight Forklift